1. Fill in each gap with one of these sequence markers to describe the procedure of papermaking.

first then (2) next after this finally

How Paper Is Made

(1) ________, logs are cut into small chips. (2)_______________ they are mixed with

water and acid. (3)________ they are heated and crushed into a heavy pulp.

This wood pulp is also cleaned and chemically whitened. (4)________ it is

passed through rollers to be flattened. (5)________ . sheets of wet paper are

produced. (6)_______ . the water is removed from the sheets which are

pressed, dried and refined until the finished paper is produced

Điền vào mỗi chỗ trống bằng từ nối theo trật tự thời gian mô tả quy trình sản xuất giấy.

1. first 2. then 3. next 4. after this 5. then 6. finally

Advertisements (Quảng cáo)

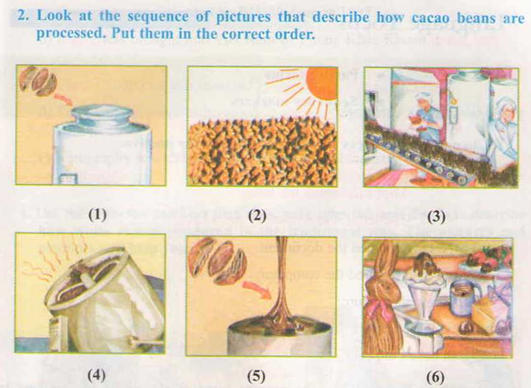

2. Nhìn tranh mô tả quá trình chế biến hạt ca-cao rồi xếp câu đúng theo thứ tự các bức tranh.

1 + d: The fruit harvest is fermented for three to nine days to kill the beans and turn them brown.

2 + a: The beans are dried in the sun.

3 + e: The beans are cleared in special machines.

4 + c: The beans are roasted to brine out the chocolate favour.

5 + b: They are shelled and ground to produce chocolate liquor.

6 + f: The liquor is made into chocolate candy or cocoa powder.

Bây giờ hãy dùng từ nối theo trật tự thời gian ở bài tập 1 để nối các câu trên lại với nhau thành một đoạn.

At first, the fruit harvest is fermented for three to nine days to kill the beans and turn them brown. Then, the beans are dried in the sun. Next, the beans’are cleured in special machines. After this, the beans are roasted to bring out the chocolate favour. Then, thev are shelled and ground to produce chocolate liquor. Finally, the liquor is made into chocolate candy or cocoa powder.